Over 400 contract inspectors, with a wide range of industry certifications & experience, are available nationally & globally, enabling us to mobilize quickly to meet your project timelines.

Mechanical & Process Equipment Areas of Inspection

- Materials Qualification

- Piping Materials

- Fabricated Materials & Equipment

- Mechanical & Rotating Equipment

- Electrical Equipment & Instrumentation

- On-Site Construction

Pipe Inspection

The inspection of Oil Country Tubular Goods (OCTG) and Line Pipe can be expensive and confusing. QAE makes it easy by:

- Reviewing the inspection order for accuracy, and compliance to your specific requirements

- Verification of proper NDT techniques

- Verification of properly calibrated equipment and utilization of trained personnel

- Verifying the traceability and documentation of the inspection parameters

- Evaluation of the material from an end users view

- Working with inspection facilities to expedite the order

QAE has extensive experience with the tubular inspection facilities in the Gulf Coast area… We know the equipment, and its limitations.

Mill Surveillance

Proper inspection procedures at the mill can reduce and/or eliminate the need for third party receiving inspection. QAE can assist by:

- Reviewing purchase orders for compliance to API, Proprietary Specifications and special requirements

- Representing purchaser during the planning, manufacturing, and inspection of product

- Verifying the completed product meets the specified requirements, and is properly documented in compliance with API, ASTM and/or the purchasers specific requirement

- Establishing specific inspection criteria and document the inspections performed

- Working with the manufacturers shipping department to minimize handling damage on the finished product when leaving the mill

QAE has associates in major tubular manufacturing facilities worldwide.

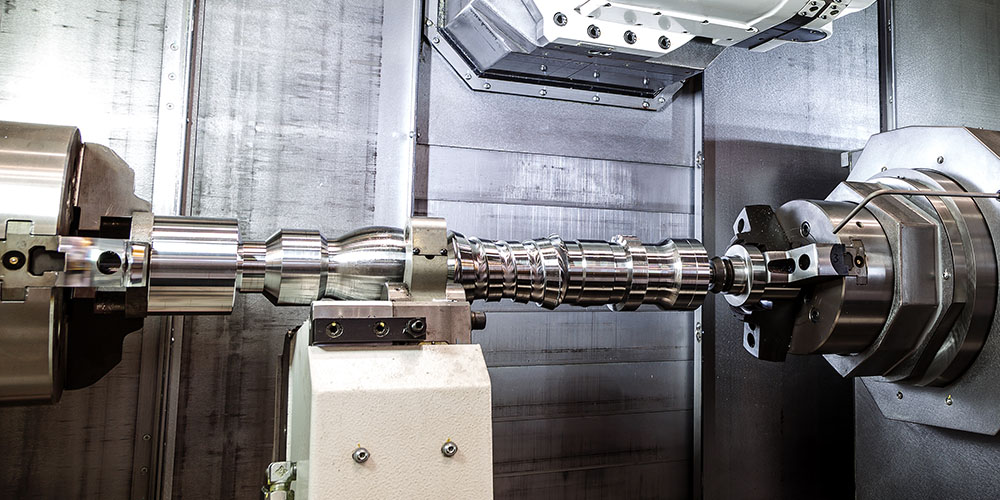

Drillstring Inspection

QAE assists in the evaluation, design, inspection and failure prevention of new/used drillstring components & handling equipment, including:

- Reviewing the inspection order for accuracy, and compliance to your specific requirements

- Establish and provide the user with methodology and data needed for drill stem design

- Recommending inspection methods and required procedures for drill pipe, rotary shouldered connections, heavyweight drill pipe, drill collars, and other drilling equipment

- Verification of properly calibrated NDT equipment and utilization of trained personnel

- Verifying the serialization and traceability of rental strings and drill equipment

- Establishing specific inspection criteria and document the inspections performed

- Recommendations on disassembly and inspection of internal working parts of equipment such as BOP’s, jars, IBOP’s, hole openers and associated equipment

- Working with the inspection facilities to expedite the order

QAE has extensive experience with drill pipe inspection facilities in the Gulf Coast area.